Product Features:

1. XKC-Y25 non-contact liquid level sensor is suitable for non-metallic containers. The product detects the liquid through the detection signal through the non-metallic container and the outer wall of the pipeline without direct contact with the liquid.It will not be corroded and damaged by corrosive liquids such as strong acid and strong alkali, and will not be affected by scale or other sundries. It can detect whether there is liquid inside outside the container or pipeline.

2. It can support high and low level output, NPN, PNP signal output (please consult the manufacturer when selecting the model).

3. The detection liquid level is accurate and stable, and it can detect cold, hot and boiling liquids.

4. Pure electronic circuit structure, non-mechanical working mode, stable performance and long service life.

5. High stability, high sensitivity, strong anti-interference ability, free from external electromagnetic interference, special treatment for power frequency interference and common mode interference, so as to be compatible with all 5-24V power adapters on the market.

6. It has a wide range of applications and strong sensing ability,can penetrate and detect the liquid level in various non-metallic containers, such as plastic, glass, ceramics and other containers. The sensing distance (container wall thickness) is max. 20mm;Liquid, powder, and particulate matter can be detected.

7. Open collector output mode, wide voltage range (5-24V), suitable for connecting various circuits and product applications.

Working Principle:

The intelligent non-contact liquid level sensor uses the inductive capacitance of water to detect whether there is liquid. When there is no liquid close to the sensor, due to the existence of distributed capacitance on the sensor, there is a certain static capacitance between the sensor and the ground.When the liquid level slowly rises close to the sensor, the parasitic capacitance of the liquid will be coupled to this static capacitance, making the capacitance value of the sensor larger, and the changed capacitance signal is then input to the control IC for signal conversion.

The changing capacitance is converted into a change of some kind of electrical signal, and then a certain algorithm is used to detect and judge the degree of the change. When the change exceeds a certain threshold, it is considered that the liquid level has reached the sensing point.

item name | spec | |||

XKC MPN | XKC-Y25-V | XKC-Y25-RS485 | XKC-Y25-PNP | XKC-Y25-NPN |

input DC(Vin) | DC5V-24V | 24V (or 12V customed) | DC 5V-12V/DC24V | DC 5V-12V/DC24V |

output method | high&low | communication | on-off(high level on) | on-off(low level on) |

required power ripple | ≤200 mV | |||

current consumption | 5mA | |||

response time | 500mS | |||

working temperature | -20~105℃ | |||

humidity | 5%~100% | |||

sensing distance | ≤20mm (container wall thickness) | |||

level accuracy | ±1.5mm | |||

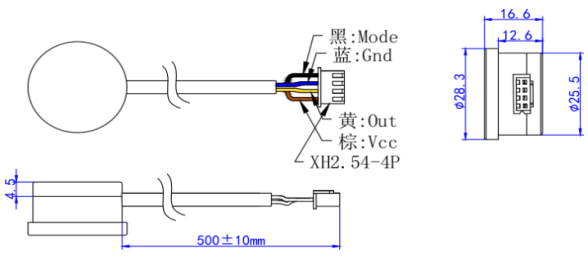

cable | 500MM (±10MM)(customed for bulk orders) | |||

wiring definition | brown(VCC)、yellow(signal outout) 、blue(GND)、black(signal option) | |||

material | PC-V0 fireproof | |||

waterproof | IP67 | |||

safety | CE | |||

environment | ROHS-2.0 | |||