1. The medicine box is a key part of the operation of the plant protection drone. During the operation, the amount of medicine in the medicine box changes dynamically. At the same time, the amount of medicine in the medicine box is important information that the ground flight controller always pays attention to. The flight controller The hand can adjust the flight control strategy of the plant protection UAV according to the amount of medicine in the medicine box. End-of-life breakpoint battery life, etc., it is more necessary to keep track of the information of the amount of medicine in the medicine box, otherwise it is prone to frequent take-off and landing, large battery loss, low operating efficiency and spray leakage. It is necessary to monitor the liquid volume of the medicine box of the plant protection drone. At present, the liquid volume monitoring of the common plant protection UAV pesticide tank is inseparable from the application of liquid level sensor technology.

2. The liquid level sensor is a common sensor for measuring the liquid level position, which can convert the height of the position into an electrical signal for output. As a simple structure and easy-to-use liquid level control device, the liquid level sensor does not need to provide power supply, nor does it have complicated circuits, and it is smaller than ordinary mechanical switches and has a longer working life. At present, it is widely used in liquid level monitoring equipment in the plant protection industry. Common liquid level sensors include float type liquid level sensors and non-contact liquid level sensors. Both liquid level sensors are equally accurate and convenient during use. The liquid level signal measured by the liquid level sensor can be sent to the terminal device such as mobile phone APP by means of wireless communication, so as to accurately record the breaking point

3. However, when installing a float-type liquid level sensor on the pesticide box of the plant protection drone, it is necessary to drill holes for installation, install the sensor in the center of the medicine box, and ensure that it extends to the bottom of the medicine barrel and the liquid to be measured The specific gravity is greater than that of the float. In addition, due to the structural design of the float type liquid level sensor, the float is prone to jamming, so it cannot be used to detect viscous liquids, and the liquid containing impurities will also cause the float to jam.

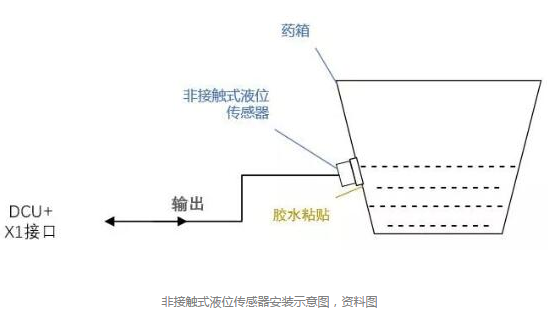

4. The non-contact liquid level sensor only adopts advanced signal processing technology and high-speed signal processing chip, which breaks through the influence of the container wall thickness and realizes the real non-contact detection of the liquid level in the airtight container. In plant protection operations, which type of liquid level gauge to choose depends on the specific situation.

Address:

Address: Email:

Email: Mobil:

Mobil: Tel:

Tel: Product

Product