In the hot summer, the ice machine is an essential equipment. It is a refrigeration mechanical device that generates ice after being cooled by the refrigeration system through the evaporator. The application of liquid level sensors in ice machines has also promoted the development of ice machines.

There is a water storage tank in the ice machine, and the function of the liquid level sensor is to detect the water level of the water tank and remind to add water. Install the photoelectric liquid level sensor at the low liquid level of the water tank. When the liquid level drops to the detection point of the sensor and the sensor detects that there is no water, it will trigger an alarm device or light a reminder. It can also realize the function of automatically stopping adding water when the water is full.

The non-contact liquid level sensor uses the principle of capacitance for detection, stable performance, high detection accuracy, and has the characteristics of small size, no mechanical moving parts inside, and long life.

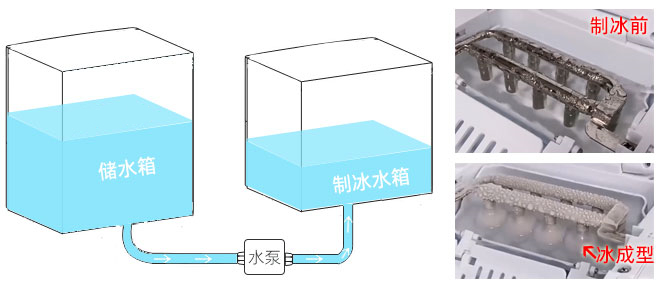

At present, the more common household ice machines usually have two water storage tanks, one is used as an ice bucket, and the other is used as a water supply for the ice bucket (hereinafter referred to as the second water storage tank).

Install one water level sensor at the low position and one sensor at the high position on the ice making bucket, then when the water level in the ice making bucket drops to a low level, the low level sensor will give a water shortage signal to remind, at this time the water pump will start from the second water storage tank pumping.

When the water level of the ice bucket reaches the position of the high water level sensor, the sensor will give a full water signal, and the water pump will stop replenishing water. In this way, the functions of automatic replenishment of water shortage and automatic stop of full liquid are realized.

Address:

Address: Email:

Email: Mobil:

Mobil: Tel:

Tel: Product

Product